Middle schoolers see future options at summer manufacturing camp

By William Renner

Hastings Area Schools

We all know one of the greatest joys of teaching is when a light bulb goes on for a student who grasps a new concept for the first time. That’s what I loved about hosting a summer camp for my middle school manufacturing students in Hastings last year.

Not only did incoming sixth, seventh and eighth graders learn new skills. They also saw those skills in action during field trips to manufacturing companies in our community—and the relevance of that learning came clear in terms of future possibilities for their lives.

My campers enjoyed all of those benefits from participating in a five-day, 25-hour summer camp. Much can be accomplished in a short time through intensive experiential summer learning opportunities, and grants are available.

The Hastings Middle School Manufacturing Camp was funded with a grant from the Fabricators and Manufacturers Association, which also provided curriculum. Additional support came from my school district and the local companies that agreed to donate time and labor for us to visit and learn.

My teaching approach would not exist without the kindness and consideration of others. I’ve always used grants and donations to buy the majority of classroom equipment and materials I use to teach technology and design in my small town.

That’s especially true for summer camp. Three local companies and a community college gave generously to make my students’ learning possible. In the end, the kids’ excitement was equally matched by the adults who took time to open up doors and share knowledge.

My goal in providing summer enrichment is to introduce campers to career paths that offer financial stability and what type of education and certifications they require. I didn’t realize how much we would also bust old stereotypes in our minds about the nature of manufacturing jobs.

We got to see skilled workers doing highly technical tasks to exact specifications in clean, modern facilities. Even I was surprised at times by the innovation and creativity involved in designing and building high-quality products efficiently.

Today’s manufacturing doesn’t fit the image of early 1900s factories. The work is dynamic, and employee learning and job growth is encouraged and rewarded. The kids enjoyed demonstrations and got to try out some equipment.

We visited FlexFab, an engineering company that designs products for extreme environments from materials such as silicone rubber. We learned about company-funded education that positions employees for success and the employer for innovation.

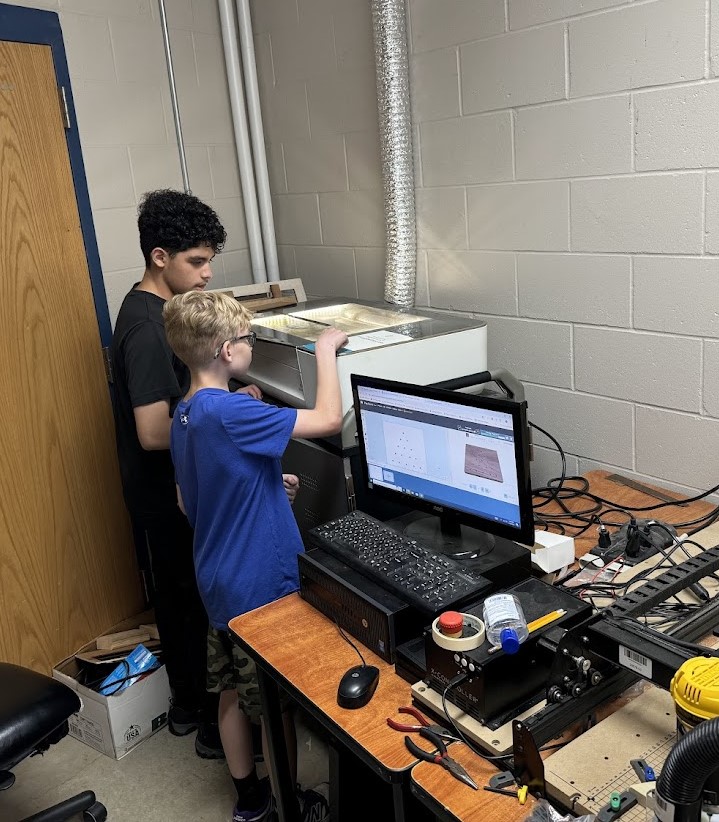

How exciting it was for my students to see computer coding that made things work on a grand scale. In my classroom, students were used to watching a table-sized X-Carve machine make cuts from their computer inputs. At FlexFab, the CNC machine was the size of a car.

Another field visit took us to Co-Dee Stamping, where 100-year-old presses that stand a story-and-a-half tall have been modified to build modern pieces and parts of products that we use everyday. Campers learned how dies and presses form metal components.

We heard from workers making parts for Bradford White Water Heaters in Middleville, Michigan. At Co-Dee they make the tray that sits underneath the water tank and the top cover that must meet specifications perfectly to properly vent gases out of the exhaust pipe.

At Hastings Fiber Glass Products, they make dependable Hot Line Tools & Equipment used worldwide to help ensure the safety of electrical line workers who handle dangerous power lines in their jobs.

The work space was orderly and air conditioned, more like an office setting than a factory. It takes precision technology and exacting standards to produce durable products that customers rely on, which requires employee training and ongoing product testing.

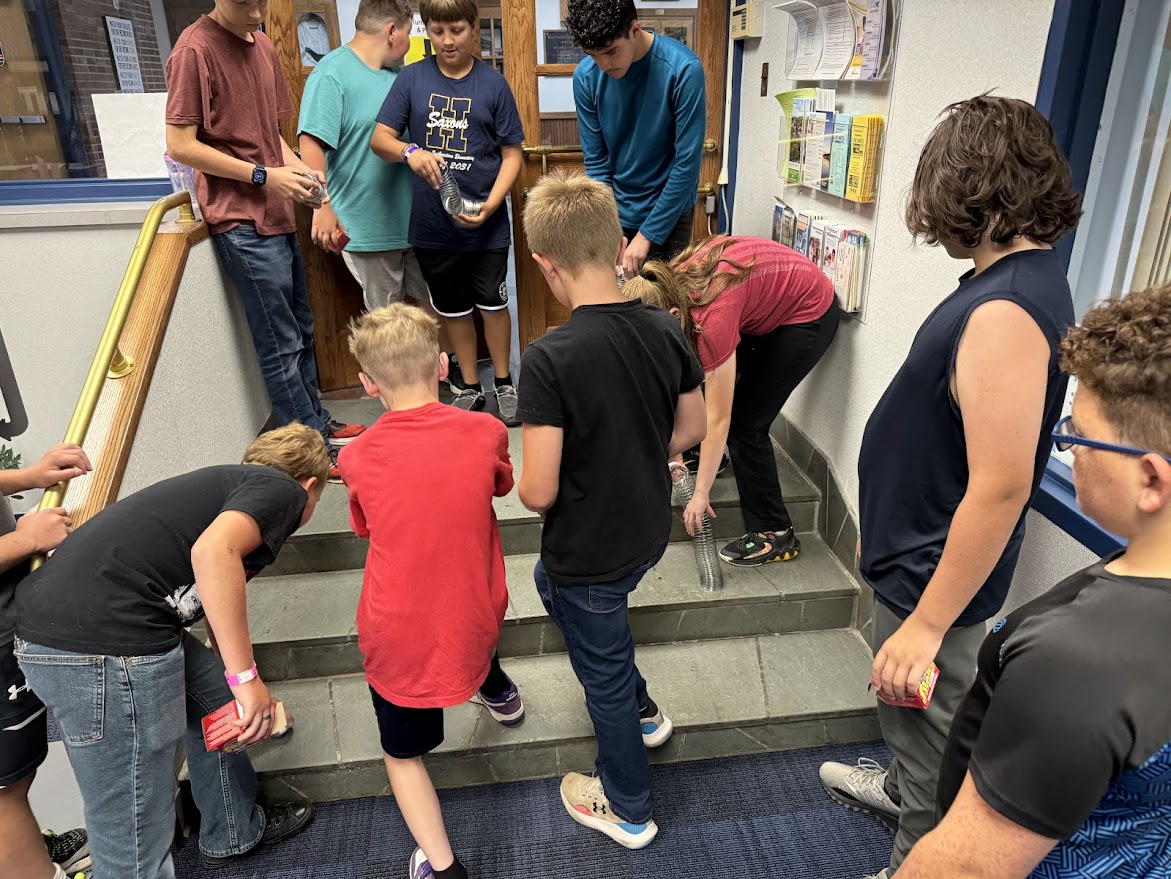

Our visit to the Kellogg Community College (KCC) Mobile Manufacturing Trailer was another highlight for campers who got to explore virtual welding and Heating, Ventilation and Air Conditioning (HVAC) systems.

KCC’s Industrial Trades Trailer allowed students to get hands-on with equipment used in HVAC systems and to learn about KCC programs that offer a path into future jobs and careers.

Back at school our curriculum explored entrepreneurship through the story of the Slinky—a wildly successful toy invented by accident in the 1940s when a naval engineer, working on springs to stabilize ships, knocked one from a shelf and saw it “walk” down in a series of arcs.

We played with Slinkies and then produced our own toys—a peg board game with golf tees. Campers used software to design pegs, printed them on 3D printers, and built boards using various tools.

Interestingly two companies we visited shared similar stories as Slinky. Hastings Fiber Glass came to be when a worker making fiberglass fishing poles had an idea to make tools for power line workers because the material does not conduct electricity—but his boss didn’t listen.

Likewise FlexFab started in the founder’s garage to become an international company. Both manufacturers employ hundreds in our town.

However, our field trips reinforced more than the entrepreneurship curriculum. Students witnessed firsthand how much math and reading is required to succeed in a skilled trade, and that understanding translates into greater motivation in school.

There are so many diverse paths to success. I always ask my students: What do you want to do? What jobs match your interests and abilities? As a teacher, I always ask myself: What can I do to make my teaching relevant and spark students’ interest in school?

Summer manufacturing camp is one of the answers. You can learn more about the grant I used to fund last year’s program at SparkForce, the FMA Foundation.

At camp students see how hard work in school can lead to rewarding careers, and I watch them grow toward a productive future. Nothing is better than seeing that light come on in a young person.

Learn more and view additional photos from the Hastings summer manufacturing camp.

William Renner uses problem solving and project-based learning to teach technology and design at Hastings Middle School.